Through preliminary meetings, research and development we created documentation that would gain approval of Tridium Niagara ‘N4’ as the software platform. The specific requirements were detailed and rigid so we had to provide evidence that we could satisfy these and meet the standards of 21 CFR Part 11.

Once approved we created the Head End within the N4 Environment and developed the considerable volume of supporting documentation. At each milestone in the development process we obtained client approval to keep things moving in the right direction.

Once the software was completed, we carried out on-site integration with the live BMS controller, extensive SAT testing and client witness testing. This was done after generating and gaining approval of the relevant commissioning and testing documents, such as validation plans, system configuration specifications.

There were several challenges with this project as the Head End had to interface with an existing control system. We also needed to decommission an existing Honeywell EBI Head End with the minimum amount of downtime possible.

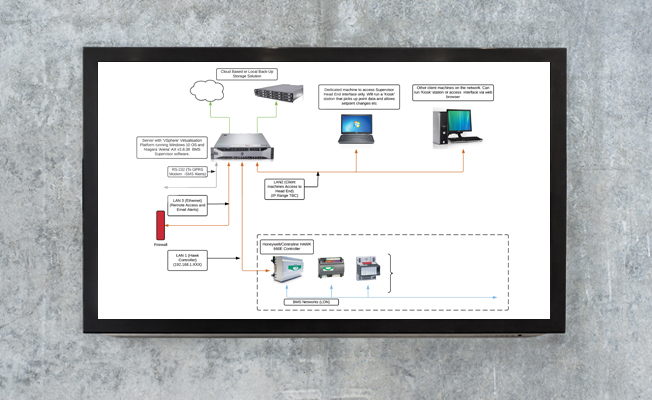

The new Head End resides on a virtual server as part of the Vectura IT infrastructure and needed to communicate with the HVAC control system as well as be accessible by network-connected end users. We worked with the Vectura IT team to navigate these challenges and maintain system security as well as accessibility.

The Outcomes

- A new Head End was successfully installed and integrated, and our extensive software and on-site testing prior to the changeover made sure there was minimal disruption or issues.

- We can now remotely access the system to assist with both scheduled and reactive servicing and maintenance, and prevent unnecessary call outs.

- The database of users assigned to the system can now be managed by system administrators.

- As well as historical data being automatically backed up and archived, permitted users can quickly and easily view history graphs and tables.

- Vectura now meet the requirements of 21 CFR Part 11, with the potential for future expansion of the system to incorporate other buildings on their Chippenham site.